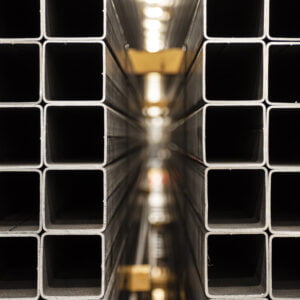

Within our suite of additional services and value-added solutions, we offer custom cutting, including longitudinal tube cutting. This service involves processing materials to specific lengths tailored to your project requirements.

The choice of cutting method depends on the tolerances permitted in your project and the intended use of the piece. Currently, our most sought-after cutting service is high-precision cutting, which includes angular cutting. Utilizing our laser machines, we achieve a tolerance of +/- 0.25mm. The laser beam focuses its high power and heat, heating the material until it reaches its melting point. At this point, the desired cut is made, allowing for intricate designs on the tubes. Our cutting can be as precise as 0.10mm, and we can create virtually any shape in our materials. This laser cutting method is considered one of the fastest and most accurate systems available, making it ideal for mass-producing precise parts. It’s particularly favored for complex projects, such as its application in the manufacturing industry, where it can be used in articulated arm cranes.

Another cutting method we offer is saw cutting, which is characterized by wider tolerances of +/- 1.0mm. This type of cut is commonly used in the manufacturing industry for applications like trailer parts, scaffolding fabrication, and other metal structures.

We can provide custom cuts on hot, cold, and galvanized steel materials, as well as on various products we manufacture, including square, rectangular, and round tubing.

Our custom cutting services can be tailored to meet the specific needs of each project and can be delivered anywhere in the United States, Mexico, and other export markets.

Allan Miller –

Excellent service, very useful